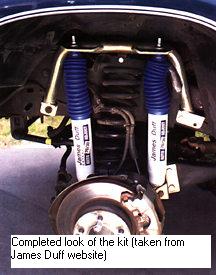

James Duff Dual Shock

Kit

PN #5260 for BII, 89-94

Ranger, 91-94 Explorer

Tools:

¾ socket and wrench

14mm socket and wrench

15mm wrench

18mm socket

3/8 and ½ drill bit

Drill

Sawzall

9/16 wrench

Torque wrench

Jackstands

4 C-clamp

Black spray paint

Punch

Time = 2 hours per-side

Tips = The sawzall is much easier

than bending metal. Also test fit all pieces before doing any cutting

or drilling, then do it again to be sure. After any cut or hole drilled,

be sure to paint the exposed metal to keep rust away.

Benefits = Dual shocks will absorb

more energy than a single shock. This means a more controlled ride

and smoother ride for occupants. With 2 shocks, heat and fade will

be less of an issue over with hard use by spreading the work load between

the dual shocks. Reduction of body roll and elimination of common

tire cupping and scissoring found on independent front suspensions.

Lastly you can choose to remove the sway bar since the dual shocks will

help eliminate that and get added articulation with greater independent

front action from the TTB.

Instructions(from the Duff instructions

plus personal input)

1. Jack up the vehicle, place jackstands

under the radius arm brackets and remove wheels with ¾ socket.

I put the stands on the frame behind the radius arm brackets and I left

the jack under the radius arm for extra support.

2. Remove the original shocks on both sides.

The top is a 15mm nut, and the bottom is a 18mm nut. Once the shock

is removed, cut the upper rubber bushings from the factory shock tower.

3. The directions tell you to bend

the shock tower at this point. I used a sawzall and trimmed the towers

along the lines that the directions stated. Also the factory plastic

wheel liner needs to be trimmed on the drivers side. Test fit the

hoops, measure and check before doing any cutting.

4. On the drivers side: remove

the lowest bolt in the steering box and attach the forward bracket of the

left side hoop loosely in place using the original bolt.

*on vehicles equipped with an engine

stabilizer, it is necessary to remove the bottom bolt from the lower bracket.

5. Align and clamp the small tab in the

center of the hoop to the coil tower. Insure that the hole in the

tab is centered vertically for a strong connection. Punch the metal

to give the drill a place to start. Remove the hoop and drill the

hole with the 3/8 bit. Then put the hoop back and bolt loosely in

place behind the shock tower ( I had to mount it in front for clearance

with the engine stabilizer bracket) with the 3/8 x 1 bolt and nylon lock

nut.

6. At the rear, check the location of the

proportioning valve on the backside of the frame. Then drill the

½ hole using the hole in the hoop as a guide. Bolt the rear

of the bracket loosely with a ½ x 1 ½ bolt and nylon lock

nut.

7. Remove the factory lower shock mount

with the sawzall and drill out to ½. Replace it with the

extended length bracket and bolt provided. Zip tie the brake line to the front

coil spring to keep from rubbing on the shock.

8. Install both shocks to the top of the

hoop in the forward most and rear most holes. Be sure that you install

the metal bushing in the bottom eye of the shock before installing them

and the shock boots. Dont use the inner 2 holes on the hoops to

mount the shocks, but rather the outer most holes.

9. Install the lower end of the shock in

the lower mount with the 100x12mm bolt. From outside in:

- Bolt

- Lower shock bracket

- Shock

- Washer

- 12mm spacer

Now put that assembly through the new

hole in the radius arm bracket. On the back side secure with a lock

washer and nut then tighten.

10. Drill 2 more ½ holes in the

radius arm using the lower shock mount for a guide. When done, you

will need the black colored backing plate on for the back side of the radius

arm. Feed the ½ x 1 ½ bolt through the backing plate,

radius arms, and out the lower shock bracket. Secure with nylon lock

nut. Do this for both sides.

11. Passenger side: same as #7.

Start there first after removing the factory shock. Do not mount

the shock until the hoop is installed:

There was no front hole in the frame for

the front of the bracket to use, so you have to drill a ½ hole

for it. Start by measuring for center and punch a hole in the shock

tower then drilling to 3/8. Once that hole is made secure the hoop

to the outside of the shock tower with the 3/8 bolt and nylon lock nut.

Now drill the front ½ hole using the hoop as a template.

Finish by doing the same with the rear of the hoop. Once both front

and rear holes are drilled in the frame, tighten with the ½ bolt

and nylon lock washers. Install the shocks and drill the holes

required in the radius arm for the lower shock bracket (same as #7)

12. Make sure all bolts are tight now.

The last step is to mount the front shocks. You should decide if

you are going to keep the front sway bar or remove it. The dual front

shocks will not require the use of the sway bar unless you do not want

any sway in corners. With out it, the vehicle will handle as before

and have improved articulation and independent action.

13. Remove the 18mm bolt in the lower end

of the swaybar link. Make sure the sway bar link is centered in the

mounting holes.

14. If you have the Dana 35 HD axle, you

will need to cut the U-shaped brackets for the sway bar. There is

a notch on the inside for a guide. Use the sawzall here also for

the job.

15. For the tie-rod adjustment sleeve,

make sure the 15mm nuts are facing toward the front otherwise they will

damage the front shock upon turning.

16. On vehicles with the straight sway

bar link (BII, 89-90 & 93-94 Rangers, 93-94 Explorer) bracket #1 goes

on the drivers side with the number facing the tire. Bracket #2 goes

on the passenger side with the number facing the tire. The top of

the sway bar link should be bolted to the sway bar with the nut inboard

of the sway bar (18mm bolt there). Disconnect the bottom bolt of

your sway bar link (18mm) and install the U-shaped bracket around the bottom

end of the sway bar link bracket. Then move turn the wheel all the

way to the left side to do the drivers side. Slide the 150 x 12mm

bolt in the bracket followed by a washer, the shock, washer, through the

U-bracket center, swaybar and out the other side. (*you will find

new words to describe this step! Be sure before installing the U-bracket,

be sure that the sway bar is centered in the factory mount.) then

use the nut to tighten. For the passenger side, turn the wheel to

the right side and follow the same steps above.

17. On vehicles with and angled sway bar

links (91-92 Explorer and Ranger) bracket #2 goes on the drivers side

with the number facing inward. Bracket #1 goes on the passenger side

with the number facing inward. Disconnect your sway bar link and

move it to the inboard side of the sway bar and the lower mounting bracket.

Install the U-shaped mounting bracket with the spacer sleeve and 2 - 7/16

washers inside the sway bar link mounting bracket. Mount the shock

outboard of the sway bar link mounting bracket and bolt all in place with

the 150 x 12mm bolt.

18. Clamp the bracket in place and unbolt

the shock. Weld the lower mount to the axle, allow it to cool and paint

around the weld to inhibit rust. Remove the shock this time using

the ½ lockwasher.

19. Tight all bolts, install wheels, torque

wheel lug nuts to 100lbs and remove the jack stands. Re-torque all

bolts after 50 miles.

Some notes on the kit. The instruction

provided have some good drawings to help assist you in your installation.

I have not included these diagram notes here. You can see that this

is not as easy as the advertising would lead you to believe. Step

#18 is something that could be optional, but if you have access to a welder

it should be done. Most all Rangers/Explorers will rub on the

front shock at full turn with 10 or wider tires on the factory rims.

Lastly, be sure to check the list for all parts before starting installation

as Duff left out the 7 - ½ nylon lockwashers on my order.

Problems after completion: The front

tires at full turns or just about there will rub on the front shocks.

This seems to happen with 31x10.50x15 tires on stock rims or wider.

I dont know if an aftermarket wheel would do that same. This is

my work around:

1. Remove the U-bracket.

2. Remove the factory sway bar

3. Use the 150 x 12mm bolt and put a washer

on the end, feed through the shock bottom, washer, into the factory swaybar

mount, then use a metal shock bushing that is the same width as the sway

bar mounts, then feed through. Bolt that with a lock washer and nut.

The tires still rub a little bit, but not

nearly like they do installed the way the kit says to. Dont bother

buying shock boots for the front shocks, they will rub off.

EXPLORER HOME | MORE

EXPLORERS

Uprgade to a more rugged suspension with Ford truck shocks from AmericanTrucks.

|